Classic & Vintage Engineering

Having been established since the 60’s we have a wealth of experience working on Classic and vintage restoration projects from steam engines to historic racing cars. We have the facilities to repair, remanufacture & reverse engineer components which are no longer available. Many of the projects we have been involved in are bespoke, one-offs, a challenge our workforce is used to handling.

On the engine side we have a fully equipped automotive engineering machine-shop where we regularly carry out white-metalling, line-boring, lead-free conversions, liner conversions, balancing, re-boring, honing, crankshaft re-grinding, surface grinding and so on (see automotive engineering list for more details) The experience we have gained in dealing with numerous different types of restoration projects coupled with our own involvement in historic motorsport gives us the knowledge to advise our customers of the best solutions whether you are looking to carry out a concourse restoration or fast road race conversion.

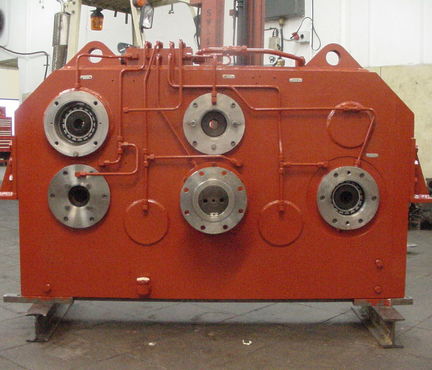

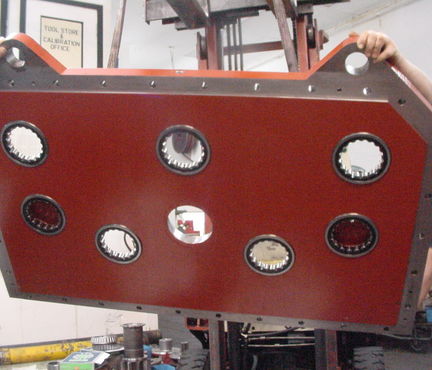

On the transmission side we have an on-site gear-cutting department and often refurbish, re-manufacture and reverse engineer everything from drive-shafts, hubs and axles to complete gearboxes. Our capabilities include gear-manufacturing, splining, keying, turning, milling, welding, brazing and general fabrication work. We have the capability to repair damaged gearboxes and can also turn rough cast casings into fully functioning gearboxes.