General Engineering

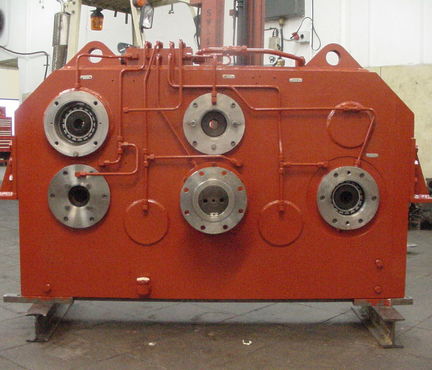

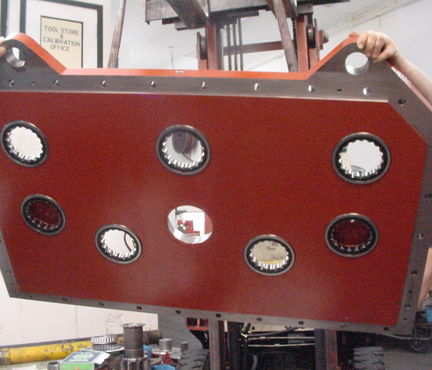

Agra’s engineering department is renowned for its high quality of workmanship and problem solving abilities. Our experienced staff can offer guidance & practical solutions to the most challenging of problems.

The workshop has a wide variety of machinery which enables us to give a fast reliable service for customers looking for small batch & 1-off components, modifications, and general repairs

Our on-site capabilities include turning, milling, grinding, boring, honing, splining, and gear-cutting, along with specialist repair services such as metal-spraying, welding and brazing.

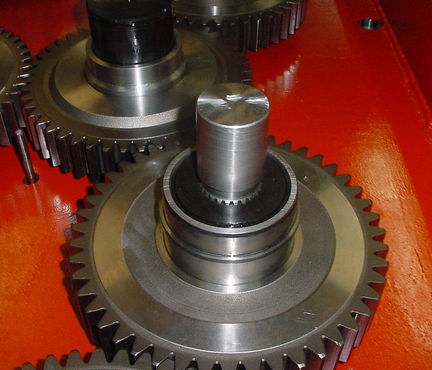

The gear-cutting department can manufacture or repair spur gears, helical gears, worm gears, dog-engagement gears, ring-gears, and sprockets in a variety of materials such as steel, cast-iron, aluminium, bronze, plastic, and tufnol. If technical drawings are not available we can reverse engineer components from samples.

All work carried out is compliant with our ISO quality assurance program and we can supply full traceability & material certs on request.